Electric vehicles are fuelling market demand for plastic components

Credit: British Plastics & Rubber magazine

22.04.2022

Share this article

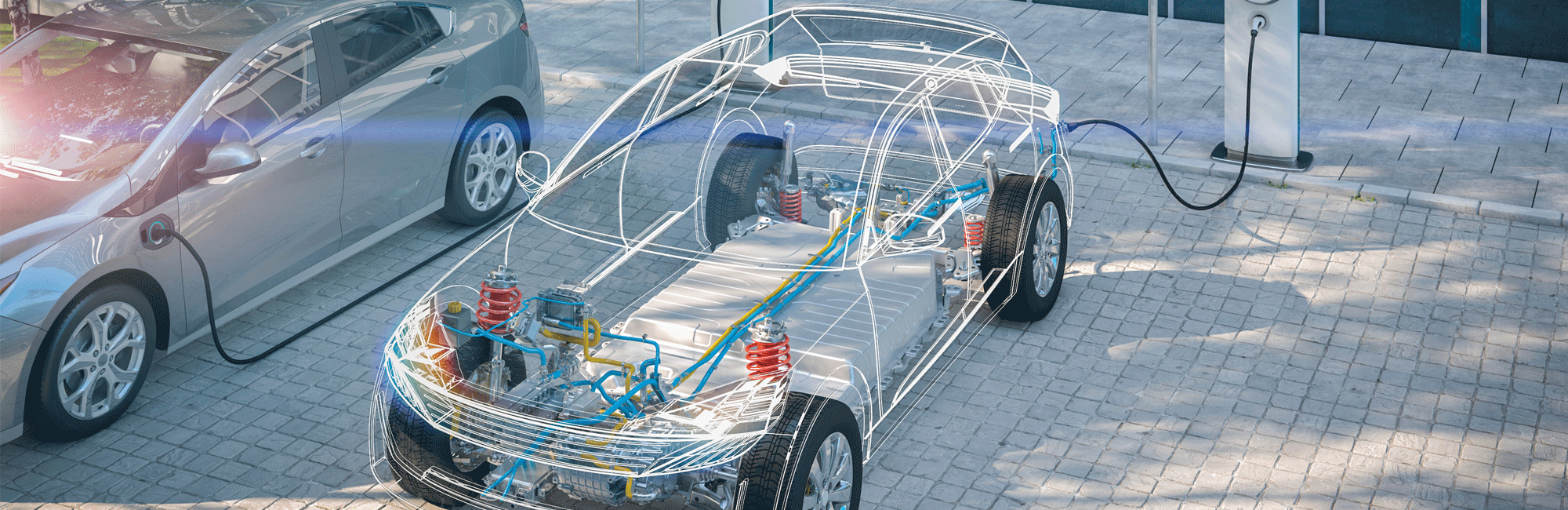

As the global momentum of EV production continues at pace, automotive manufacturers are increasingly turning to alternative component materials to help improve the overall efficiency of electric vehicles.

With government regulations on vehicle emissions, a key driver for EV growth, most automotive manufacturers are now looking at using plastics as base materials to build automotive parts.

Plastics and composites have been used in vehicles for decades, mainly due to their lightweight properties which can be 30% to 50% less compared to metal. Today, lightweight plastics can make up 50% of a vehicle’s volume, but only 10% of its weight. Therefore, it is a natural development that plastic components are being incorporated into electric and hybrid vehicles. This helps to help offset the weight of electric motors and battery housings, and provides the performance and efficiency.

The perfect material for design teams

There are further benefits with plastic components including their exceptional electrical and thermal insulation qualities, and its resistance to corrosion. For those in the design field, plastic remains an extremely flexible material, one that can be incorporated into even the most complex components with relative ease and freedom. And for high volume production, an important factor as EV production continues to increase, it’s possible to remain pleasingly cost-effective.

A hurdle the industry is acutely aware of is achieving the necessary levels of trust in the materials in order to change design practices towards using non-metallic materials. Overall, however, concerns around using plastic are outweighed by the various advantages that it can clearly offer.

Going forwards, it’s easy to imagine plastic components, their mountings and their housings all taking on an even more crucial role in the design of electric vehicles. Battery ranges between charges are already important, of course, and they will need to continue to improve. Keeping vehicles on the lighter side, perhaps with increased usage of reinforcing materials such as glass and carbon fibre, will inevitably lead to further gains in the drive towards energy efficiency levels that were previously thought unachievable.

Related articles:

- British Plastics and Rubber, Interplas insights - 'How electric vehicles are fuelling market demand for plastic components' - Page 11 - April 2022

- FastFix Technology - 'Increasing demand for plastic components in the automotive industry' - 20.05.2022

- Fastener & Fixing - 'Increasing demand for plastic components in the automotive industry' - Page 162 - July 2022

- Fastener & Fixing - 'Increasing demand for plastic components in the automotive industry' - 11.08.2022