SERVICES

Quality

TR provides a level of product quality which minimises the production of non-conforming fasteners with the objective of zero defects and six sigma processes for specific characteristics

Customer specific quality standards can be provided as required

We achieve these higher quality standards with an array of processes including:

- Electronic PPAP

- Supplier development and strategic sourcing

- Camera, laser & roller sorting

Our quality activities

QUALITY OBJECTIVE

Quality system

Through our policy that quality is everybody’s responsibility, we work towards our quality objective to reduce the cost of poor-quality year-on-year, improving customer satisfaction and generating value for our customers.

We have been assessed against the following internationally recognised standards:

- ISO 9001:2015

- ISO 14001

- IATF 16949

- ISO 17025

- EN 9120

- ISO 27001

CUSTOMER

Customer quality

We understand that every customer has unique quality requirements.

We aim to align our service with our customers needs and can provide appropriate controls through our operational processes.

We focus on understanding the needs and expectations of our customers through our Customer Quality team. Including contract review of supplier quality manuals, quality performance requirements and product approval requirements.

Our group operations scope of activity:

- Stockholding and supply of fastenings for industrial applications, with traceability to source of manufacture, and with full lot traceability as per contractual requirements

- Product design and development activities

SUPPLIER

Supplier quality

Our Supplier Quality Managers and Supply Quality Engineers (SQE’s) are an integral part of our team delivering stakeholder requirements.

Our core SQE activities include:

- Support new product approval

- Assessment, approval and development of suppliers based on key customer requirements

- Supplier quality resource in all regions to support escalated issues

We have supplier quality resource in all regions to ensure we can meet the needs of the business:

- Assessing potential suppliers

- Developing new suppliers

- Supporting new product approval activities including control plan and FMEA sign-off at production sites

- Supporting escalated issues

PRODUCT

Product quality

Our Product Quality teams are focused on three key areas:

- Ensuring customer satisfaction through APQP processes

- Enabling sales growth through the availability of product approval documentation

- Minimising risk through standardised global processes and effective complaints management

APQP product processes:

- Control plan and FMEA review, run at rate review, packaging specifications, sample approval process, 90-day launch plan for inspection

- Common part availability across our sites including product approval documentation

- Standardised processes to support our global operations teams, including process monitoring, data governance, and change management backed up by training manuals and functional delivery teams

Awards

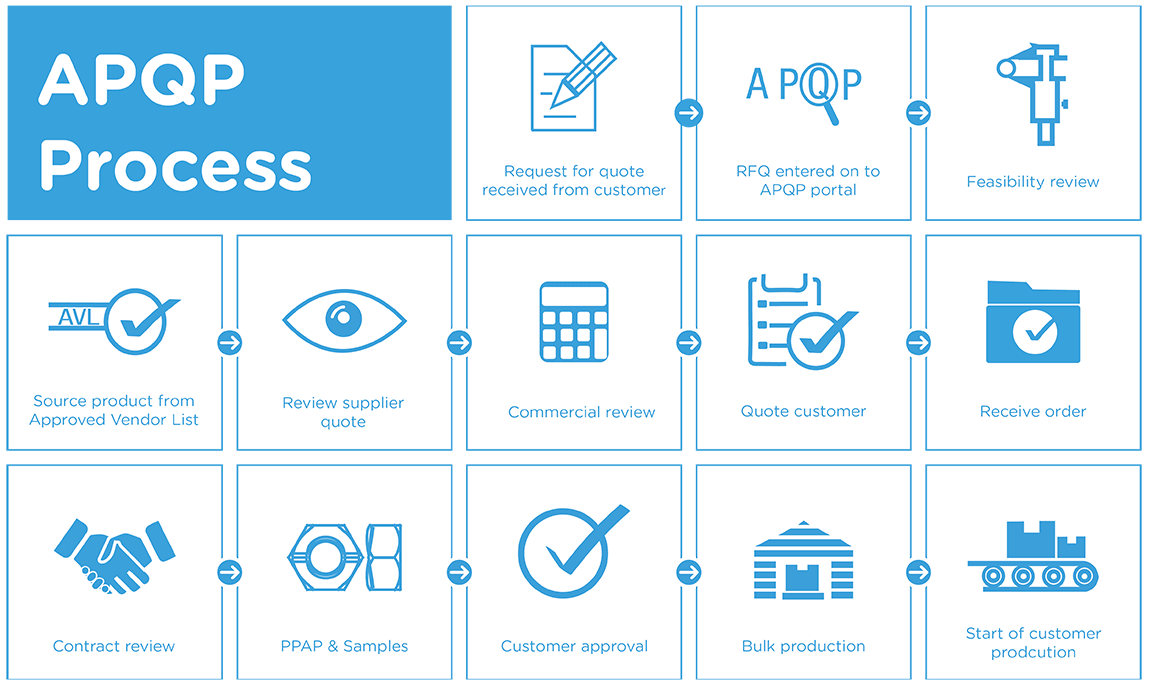

Advanced Product Quality Planning

To ensure all quality requirements are met for the parts we supply, TR adopts an APQP process for all automotive customers which can be utilised on request for any sector.

1. Request for quote received from customer

A request for quote can be received in a number of ways: through our external sales team, existing accounts can use their dedicated account manager or enquiries can come through our website.

Enquiries are then qualified and we ensure we have the required documentation to enable us to proceed.

2. RFQ entered on to APQP portal

Whether new or 'carry over' parts, all automotive and designated enquiries are entered onto the APQP portal.

This TR bespoke intranet portal is designed to set the following APQP tasks into a measurable timeline.

Each task is monitored to ensure that our customers pre-production timescales are met.

3. Feasibility review

All drawings and standards are reviewed by TR Feasibility Engineers to ensure that the full extent of the customers requirements are understood.

Once critical and safety critical characteristics are identified, the Engineers work closely with the New Product Introduction Team to ensure that the correct supplier is aligned with the requirements.

4. Source product from Approved Vendor List

The TR automotive AVL is managed by a dedicated Commercial, Quality and Sourcing team.

Suppliers are added to/removed from the AVL based on business needs or supplier performance.

The AVL team is supported by Supplier Quality Managers in Europe and Asia. The SQM team audits suppliers on an on-going schedule and develops suppliers based on improvements identified.

5. Review supplier quote

It is the responsibility of the Feasibility Engineers to compare the suppliers capability of manufacturing against the customers requirements, identifying any differences and ensuring that these are understood and approved.

6. Commercial review

It is the responsibility of the relevant TR division to complete a cost model to assess any additional costs pertaining to servicing the account e.g. stockholding, premises, labour costs and the movement of the product.

This is then reviewed in line with turnover and working capital expectations and authorised accordingly. This enables us not only to remain competitive, but can also help in offering additional value to both parties through alternative logistical solutions.

7. Quote customer

A system quotation is created for the customer to meet their exacting requirements and timelines.

8. Receive order

The New Business Introduction team reviews internal commercial, operational requirements and logistic needs against the original quotation.

9. Contract review

Customer and supplier understanding of the product engineering is only part of the contract review to ensure that not only does TR get correct product to the customer but that the correct volumes are with the customer in their timescales for production.

The NBI Team are not only responsible for getting product to the customer in time for start of production (SOP), they also have the responsibility to ensure that on-going production requirements are understood and managed.

10. PPAP & samples

TR operates automotive product approval processes based on standardised Production Part Approval Process (PPAP) documentation and has established Group wide approval documents using Automotive Industry Action Group (AIAG) templates.

Our global product approval strategy allows us to provide common parts to multiple customer locations on a reduced timeline. We have established customer specific requirement templates for TR global customers.

11. Customer approval

It is a business key performance indicator (KPI) to achieve 100% first time product approval. This KPI is measured and monitored on a monthly basis by the Group Quality Director and Customer Quality Manager.

12. Bulk production

Planning at this stage is key and discussions take place with both our own manufacturing sites or designated AVL vendors to ensure we can meet the customers contracted expectations.

The logistics of moving product around the globe in line with customer assembly schedules and legislative requirements is critical to TR's Supply Chain Management (SCM).

13. Start of customer production

On-site technical support is available during initial build stage. Logistics are constantly monitoring the ramp up to full production to ensure there are no supply shortages or any areas of risk that could impact.

Contact us

Literature download

View and download all of our brochures and product information using the link below.

Not found what you're looking for?

Complete the form below and one of our team will get back to you:

* is a mandatory field

TR - Full service provider

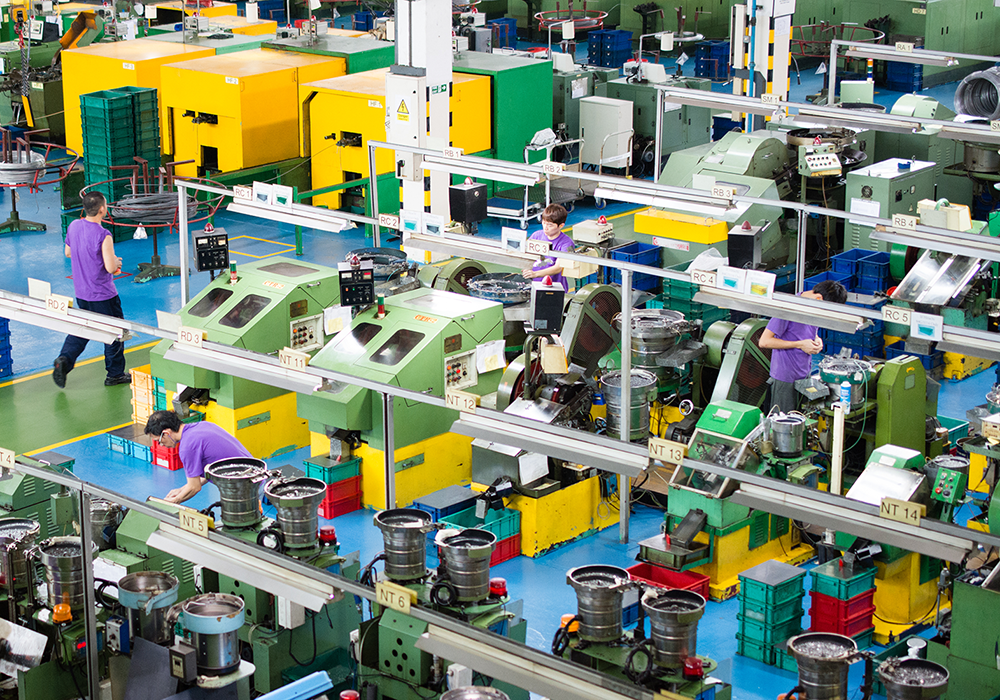

Manufacturing Our manufacturing network spans two continents and represents approximately a third of the Group’s business - Find out more

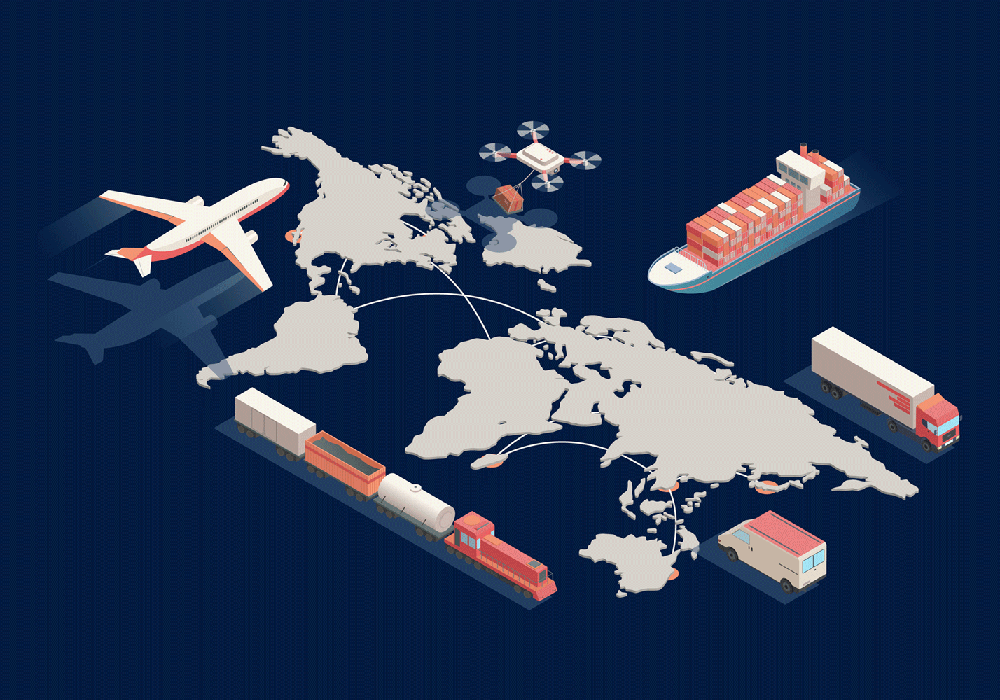

Manufacturing Our manufacturing network spans two continents and represents approximately a third of the Group’s business - Find out more  Logistics Whether dealing with niche manufacturers or multinational household names, at TR we tailor our services to our customer requirements - Find out more

Logistics Whether dealing with niche manufacturers or multinational household names, at TR we tailor our services to our customer requirements - Find out more  Technical support services TR’s engineering and technical team use their experience and skills to solve fastener challenges - Find out more

Technical support services TR’s engineering and technical team use their experience and skills to solve fastener challenges - Find out more  Sourcing The very nature of our business necessitates a large and varied supply chain which presents both challenges and opportunities - Find out more

Sourcing The very nature of our business necessitates a large and varied supply chain which presents both challenges and opportunities - Find out more  Trade bodies and associations TR Fastenings is proud to be members of the following trade bodies and associations - Find out more

Trade bodies and associations TR Fastenings is proud to be members of the following trade bodies and associations - Find out more  TR in industry TR supplies components to over 5000 companies globally across a wide range of industries - Find out more

TR in industry TR supplies components to over 5000 companies globally across a wide range of industries - Find out more