TR springs to the challenge to develop innovative new solution for automotive customer

12.11.2024

Share this article

As the EV market grows worldwide, automotive designers and engineers, together with manufacturers, are completely rethinking the design of EVs, in order to provide consumers with the most advanced, high-tech specifications they now expect, without compromising on passenger comfort and user experience in any way.

The requirement

Finding the right solution is my passion, and working alongside our customer on this project was an incredible opportunity to bring that to life. Leveraging our experience and global supplier network, we designed a solution that not only met their precise needs but also provided enhanced functionality and durability.

The Solution

The product

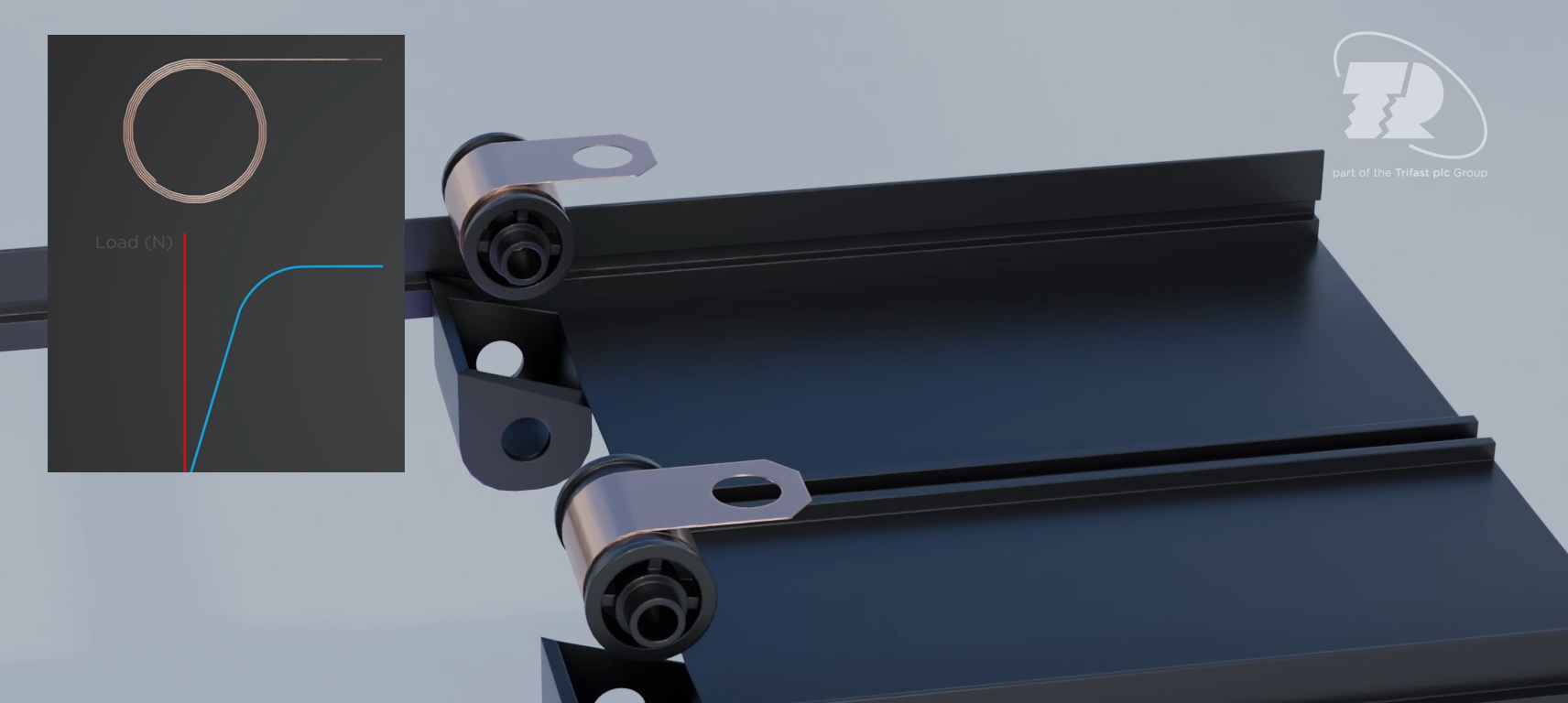

To create a smooth and continuous motion of the central console mechanism, TR had to match the spring performance with a suitable damper to ensure that the console travelled smoothly and at a continuous speed, both in a stationary vehicle or when driving over a bumpy road.

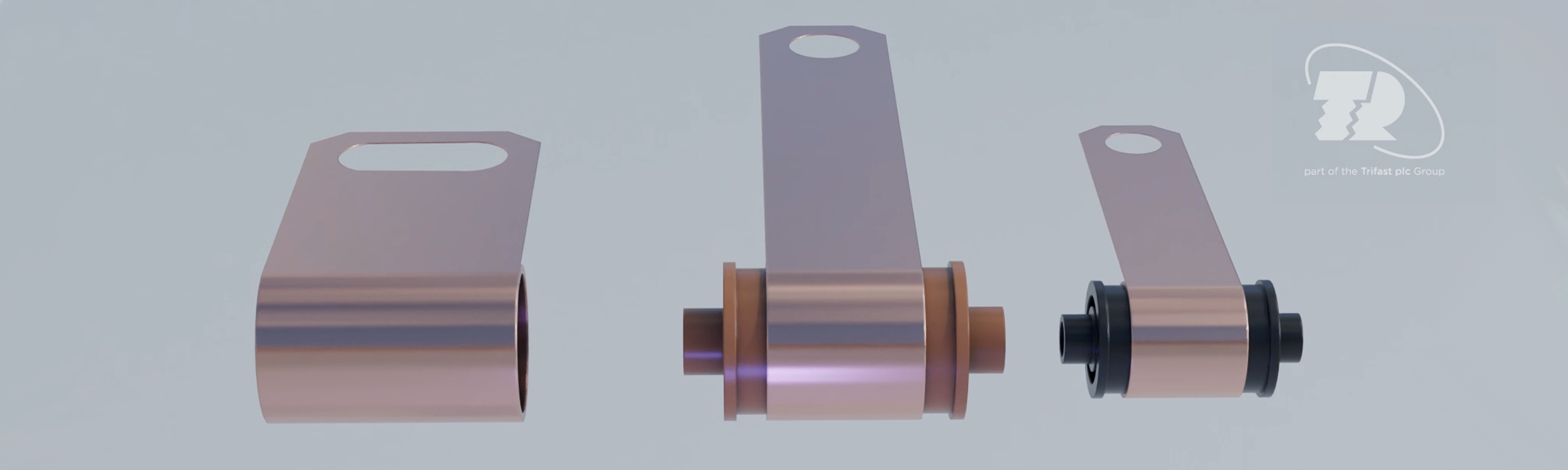

Understanding the application design requirements, TR developed a spring and spool assembly which translates linear motion into rotation. The assembly was tailored to the application to fulfil its function smoothly and without noise.

To achieve this, the spool was specifically designed to align with the geometry of the spring. Controlling and lubricity, as well as manufacturing the spool of a specific polymer, low static and dynamic sliding friction against mating surfaces was achieved.

TR was also able to support the customer with cost efficiencies of this product. By reducing the size of the spool, not only would this reduce material costs, it would also speed up installation time. TR used a combination of technical insights and production techniques to produce a superior product that met the brief of this challenging application.

Project Conclusion

TR rose to the challenge by providing top-class engineering insights and support, delivering precisely what the customer needed to bring their electric vehicle design to life. By integrating innovative solutions and collaborating closely with global teams, TR developed a custom spring and spool system tailored to the customer’s unique requirements. This solution met the complex demands of the central console mechanism while maintaining smooth functionality, reliability, and cost efficiency.

As the EV market continues to expand, TR remains committed to pushing the boundaries of fastener technology, supporting automotive manufacturers in designing and producing advanced components without sacrificing passenger comfort or user experience. Through this project, TR demonstrated its dedication to innovation, meticulous engineering, and understanding the needs of both customers and the evolving electric vehicle industry.

TR is leading the way in design engineering and manufacturing with more than 55,000 products across its portfolio. It supplies components to more than 5,000 companies globally across a wide range of industries from its facilities in 18 countries encompassing seven manufacturing sites.

Patrik Ringdahl, Project Engineer at TR commented;

Related articles:

- Fastening & Bonding: TR springs to the challenge for automotive customer - 21 November 2024

- Industrial Technology: TR springs to the challenge for automotive customer - 21 November 2024

- Electrical Engineering Magazine: TR springs to the challenge to develop innovative new solution for automotive customer - 20 November 2024

- NEAA: TR springs to the challenge to develop innovative new solution for automotive customer - 19 November 2024