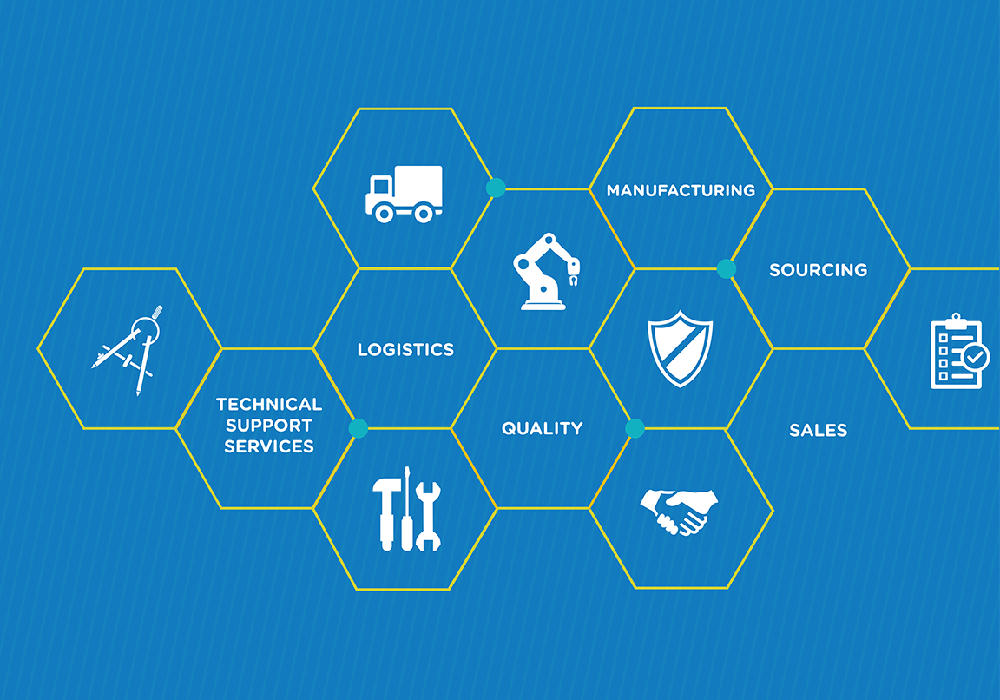

SERVICES

Global sourcing & procurement

Optimising our vendor knowledge to provide a high level of support to our customer base to ensure we meet their objectives

TEAM

Global Sourcing Team

The Global Sourcing team have extensive knowledge of fasteners and the marketplace and have an average of 25 years’ experience in the industry.

This team perform a critical function within the TR Group. They are a key support to the Commercial team through their sourcing expertise, product knowledge and vendor know how. Their function is to work closely with our nominated vendors to ensure speedy and effective sourcing, leveraging spends to offer our customers a quality and commercial proposal.

The team provides expert support through the TR global enquiry portal utilising the substantial customer parts database to enable timely responses. The wealth of data from the portal guides us to identifying new product opportunities where we require specific vendor sourcing support. New product introduction is a vital part of maintaining a comprehensive portfolio of products for the benefit of our customer base.

VENDORS

Vendor selection

We treat our vendors with respect in all our dealings as vendor relationships are extremely important and we rely on their support.

Strategic partner: TR branded product and our core products for resale.

Supplier controlled: Branded products (non-TR) and customer nominated suppliers.

Leveraged suppliers: Standard parts (bought to a specific standard).

Transactional buying: Low cost products bought daily.

Supply Chain work on developing strategic partners in this category, migrating those relationships to strategic partner category.

APPROVED VENDOR LIST

Vendor management

It is extremely important to ensure that there is a managed balance between TR’s customer requirements and TR’s supplier capability. To manage this requirement all potential suppliers to TR must go through a very strict process of vendor appraisal.

The process is managed by an Approved Vendor List (AVL). The AVL team is drawn from our Quality, Sourcing and Commercial departments. To satisfy the team's requirements, the supplier must comply with the following process of evaluation.

Annual vendor assessments are conducted on key suppliers, and strategic new ones who are being introduced.

QUALITY

Supplier Quality Engineers

Supplier Quality is there to ensure that we meet our customer’s stringent requirements.

We have divided performance management into five key areas.

PROCUREMENT

Procurement

As a full service provider, FSP, to many customers with very differing product requirements, we have inevitably a wide product range to service and supply. New suppliers go through a stringent process before they are added to our vendor base and are assessed as part of the procurement process, and existing AVL suppliers are audited.

Training on subjects such as the modern slavery act, conflict minerals etc is part of the DNA of our teams, and sustainability is high on the current sourcing and procurement agenda.

Demand planning has never been more important as customers communications and technology has developed utilising sophisticated ERP and EDI systems, and through customer portals to request shipments. Interpreting and fulfilling this demand through our Material Resource Planning (MRP) teams is key to supplying OTIF – one time and in full. Working closely with our sourcing colleagues is vital.

PRODUCTS

Product line cards

It is impossible for our seven manufacturing sites to provide the full range of product that we supply to our customer base.

We focus on cold forged specials to drawing, therefore we source and procure product in volume from manufacturers who have areas of speciality that are different to the product that we produce, and in other materials such as Plastics and Rubber Hardware.

As an FSP we have differing VMI systems in place where we manage the complete BOM - bill of materials for customers. We are often asked to take part in vendor reduction exercises and Kaizen events on customer sites as they focus on the TCO (Total Cost of Ownership). They require us to consolidate and manage other vendors’ products, including well known industry brand names. This ensures that they keep the volume and instead distribute to us. Over time we have built up relationships with many of these companies who are pleased to have the association with TR. We 'manage' their product often going down a route to market that they themselves could not easily reach.

Please see a snapshot of some of these suppliers:

Quick links

Sustainability Our sustainability strategy, securing a sustainable future, sets out the blueprint for an exciting new chapter for Trifast, as we make a step change in the ambition and reach of our sustainability programmes - Find out more

Sustainability Our sustainability strategy, securing a sustainable future, sets out the blueprint for an exciting new chapter for Trifast, as we make a step change in the ambition and reach of our sustainability programmes - Find out more  Quality TR provides a maximum level of product quality which prevents the production of non-conforming fasteners with the objective of approaching zero defects for specified characteristics - Find out more

Quality TR provides a maximum level of product quality which prevents the production of non-conforming fasteners with the objective of approaching zero defects for specified characteristics - Find out more  Services Since it was established in 1973, TR Fastenings has evolved from a fastener distributor into a global assembly partner - Find our more

Services Since it was established in 1973, TR Fastenings has evolved from a fastener distributor into a global assembly partner - Find our more Contact us

Literature download

View and download all of our brochures and product information using the link below.

To be qualified as a supplier to TR just complete the form below and the team will get back to you

* is a mandatory field