TR Self Clinch Recess Panel Fastener installation

- Punch or drill the mounting hole. Do not deburr the hole or perform any other secondary operations

- Place fastener into anvil recess then place sheet over the fastener spigot

- Apply squeezing force, ensuring that the punch and anvil surfaces are parallel, until the retainer shoulder makes contact with the face of the sheet

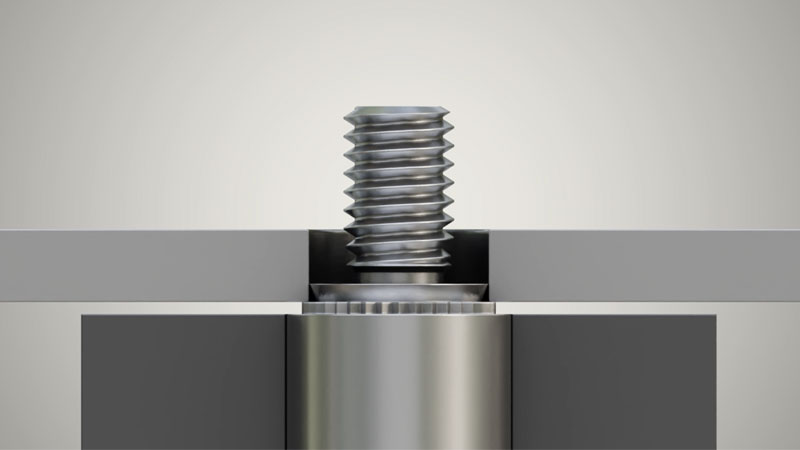

1 Step 1

Select the appropriate hole size from the table below for the fastener size required. Punch the hole diameter into the sheet. Place fastener into anvil recess.

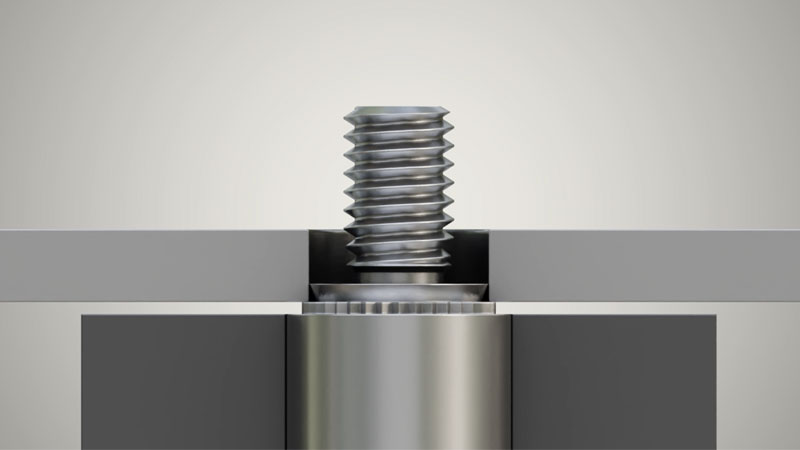

2 Step 2

Place the sheet over the fastener spigot so that it rests on the fastener serrations. Ensure both plate and fastener are aligned along the same axis.

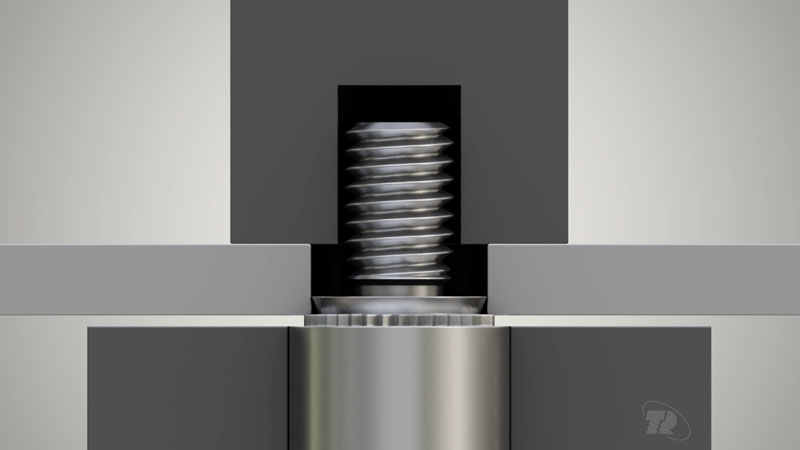

3 Step 3

Apply squeezing force, ensuring that the profiled punch and anvil surfaces are parallel, until the retainer shoulder makes contact with the face of the sheet.

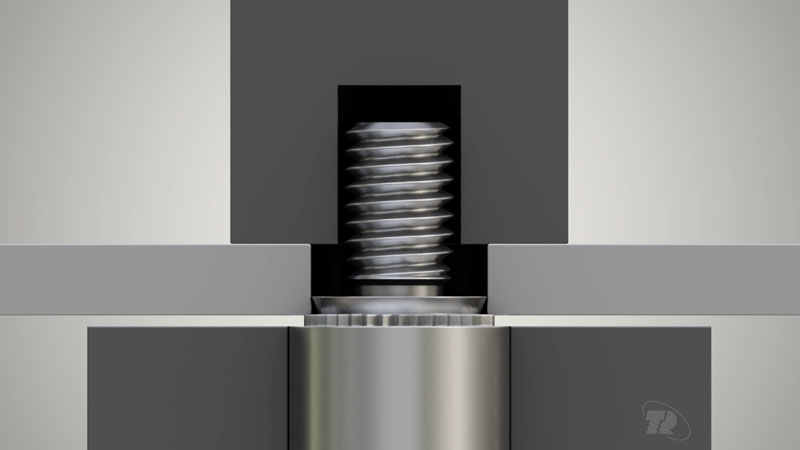

4 Step 4

The serrations if properly installed will provide torsional (rotational) resistance. After installation the spigot joint should be flush with the sheet.

Installation animation

Hole sizes - metric (mm)

| Thread size | M3 | M4 | M5 | M6 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Min sheet thickness | 1.53 | 1.53 | 1.53 | 1.53 | |||||||

| Hole size in sheet +0.08 | 6.73 | 7.90 | 8.74 | 10.49 | |||||||

| Min. distance to hole C/L from edge | 6.35 | 7.87 | 8.63 | 9.65 | |||||||

Hole sizes - inches

| Thread size | 4-40 | 6-32 | 8-32 | 10-24 and 10-32 | 1/4-20 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. in sheet thickness | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | |||||||||

| Hole size in sheet + 0.003 - 0.000 | 0.265 | 0.281 | 0.312 | 0.344 | 0.413 | |||||||||

| Min. dist hole C/L to edge | 0.255 | 0.285 | 0.315 | 0.345 | 0.385 | |||||||||

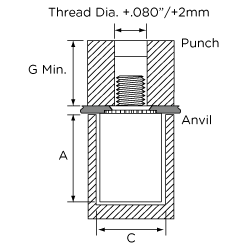

Tooling

|

Thread size | A mm 0.05 | C dim 0.05 |

|---|---|---|---|

| M3 | 8.76 | 8.2 | |

| M4 | 11.05 | 9.8 | |

| M5 | 11.05 | 10.69 | |

| M6 | 14.35 | 12.29 |