TR Self Clinch Low Profile Panel Fastener installation

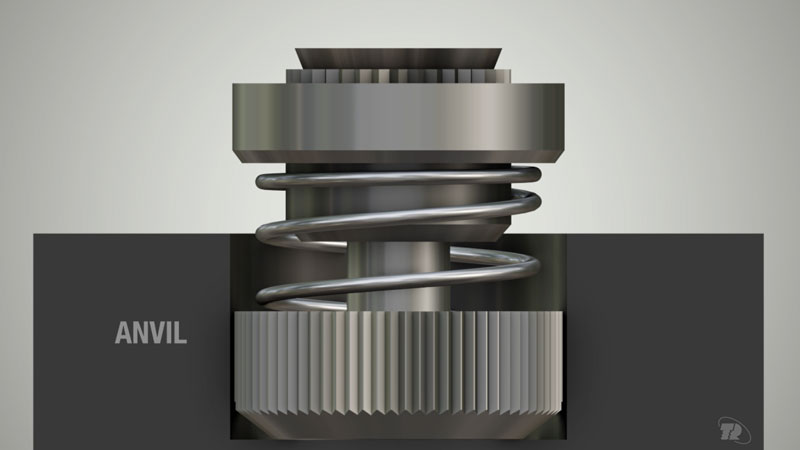

1 Step 1

Select the appropriate hole size from the table below for the fastener size required. Punch the hole diameter into the sheet. Place fastener into anvil recess.

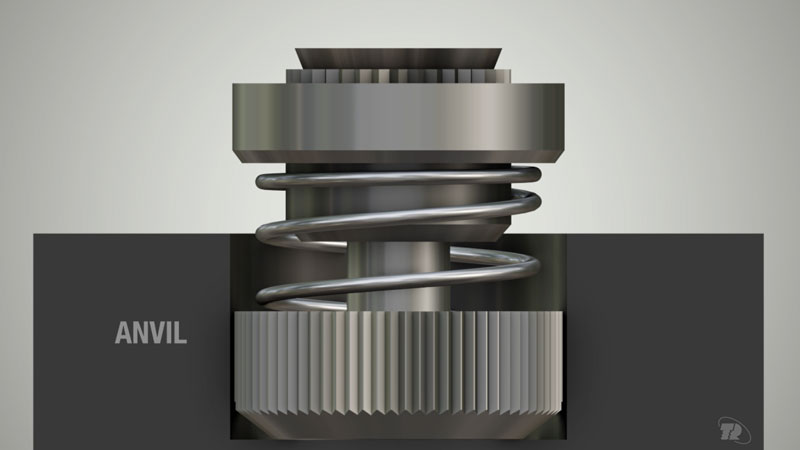

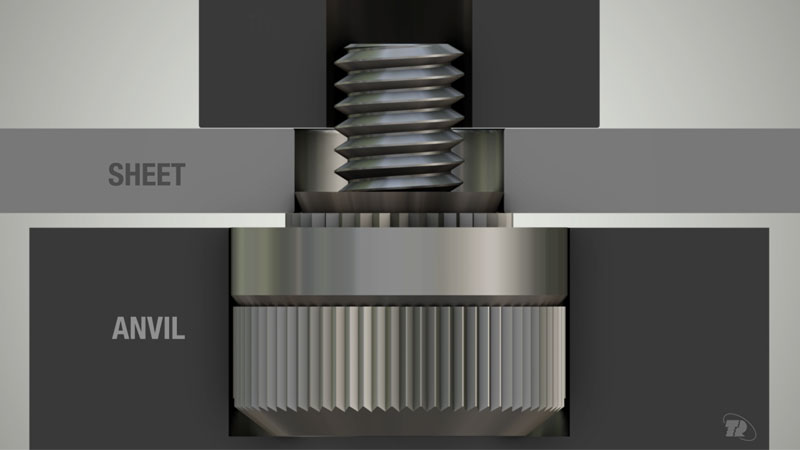

2 Step 2

Place the sheet over the fastener spigot so that it rests on the fastener serrations. Ensure both plate and fastener are aligned along the same axis.

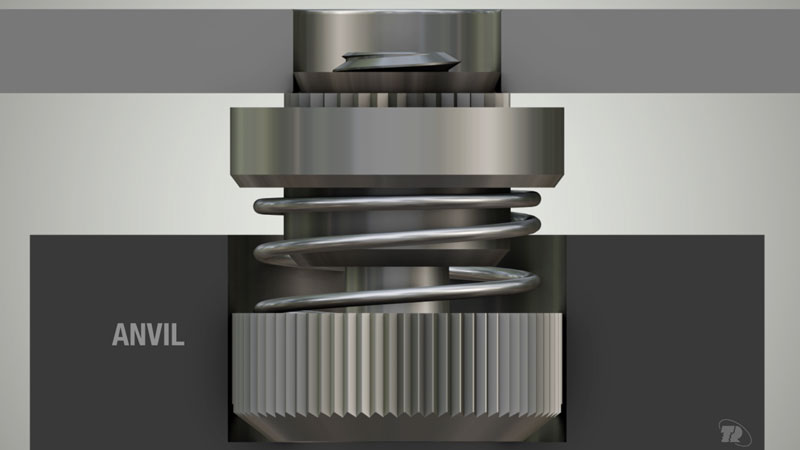

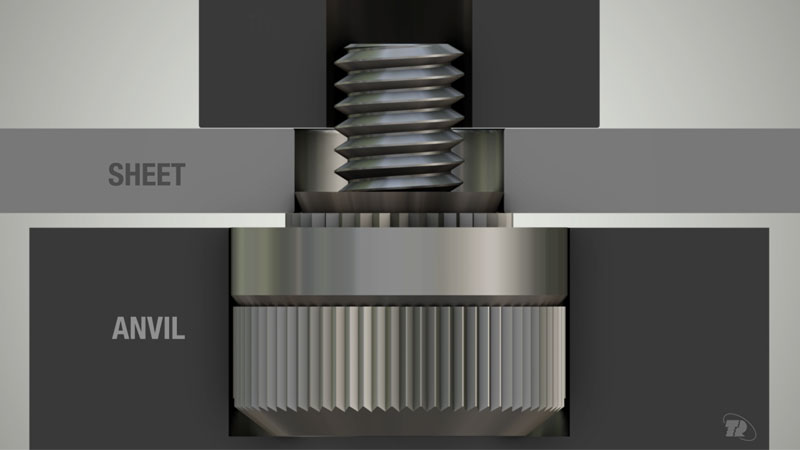

3 Step 3

Apply squeezing force, ensuring that the profiled punch and anvil surfaces are parallel, until the retainer shoulder makes contact with the face of the sheet.

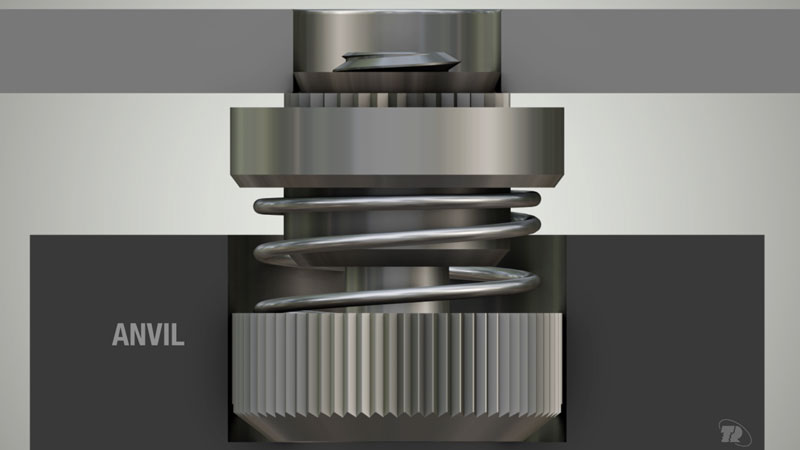

4 Step 4

The serrations if properly installed will provide torsional (rotational) resistance. After installation the spigot joint should be flush with the sheet.

Installation animation

Hole sizes - metric (mm)

| Thread size | M3 | M4 | M5 | M6 | |||

|---|---|---|---|---|---|---|---|

| Type | TR-PF31 | TR-PF32 | TR-PF31 | TR-PF32 | TR-PF31 | TR-PF32 | TR-PF32 |

| Min sheet thickness | 1 | 1.5 | 1 | 1.5 | 1 | 1.5 | 1.5 |

| Hole size in sheet +0.08 | 5.5 | 6.4 | 8 | 9.5 | |||

| Min distance to hole C/L from edge | 6.6 | 7.37 | 8.3 | 8 | 9.65 | ||

Hole sizes - inches

| Thread size | 4-40 | 6-32 | 8-32 | 10-24 and 10-32 | 1/4-20 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | PF3O | PF31 | PF32 | PF3O | PF31 | PF32 | PF3O | PF31 | PF32 | PF3O | PF31 | PF32 | PF32 |

| Min. sheet thickness | 0.03 | 0.04 | 0.06 | 0.03 | 0.04 | 0.06 | 0.03 | 0.04 | 0.06 | 0.03 | 0.04 | 0.06 | 0.06 |

| Hole size in sheet + 0.003 - 0.000 | 0.205 | 0.221 | 0.252 | 0.314 | 0.377 | ||||||||

| Min. dist hole C/l to edge | 0.265 | 0.285 | 0.295 | 0.335 | 0.385 | ||||||||

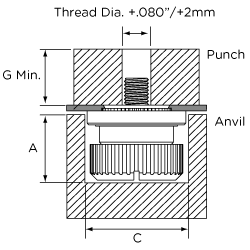

Tooling

|

Thread Size | A mm 0.05 | C Dim 0.05 |

|---|---|---|---|

| M3 | 7.49 | 10.69 | |

| M4 | 7.87 | 12.29 | |

| M5 | 7.87 | 13.87 | |

| M6 | 9.27 | 16.26 |