Plas-Tech® 30 installation guide and hole sizes

This article provides an installation guide for the high performance Plas-Tech® 30 Screws for Plastics.

Installation animation

The illustrated moulded boss features a 1 Degree inclusive tapered hole. However, it is not a prerequisite. It is commonplace for these screws to be installed into drilled holes also.

|

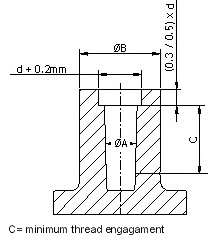

To identify a suitable hole size for a selected screw diameter, choose a material from the boss geometry tables below closest to the application boss type and multiply the value in column A by the nominal external thread diameter. For example: A 3.0 diameter high performance Plas-Tech® 30 Screw for Plastic being installed into ABS would require a 0.8 x 3.0 = 2.4mm guideline hole diameter (where 'd' = nominal external thread diameter). Where possible, the inclusion of a counter bore is recommended. A counter bore helps reduce the risk of damage to the top of the boss, reduce stresses in the boss, helps with screw alignment and acts as relief for any material extruded to the head of the screw, allowing flush finishes. To calculate the counter bore diameter, add 0.2mm onto the selected published screw head diameter. |

| Table 1 | Table 2 | |||||||

|---|---|---|---|---|---|---|---|---|

| Material | - A - | - B - | - C - | Material | - A - | - B - | - C - | |

| ABS | 0.80d | 2.00d | 2.00d | PC GF30 | 0.85d | 1.80d | 2.00d | |

| ABS/PC | 0.80d | 2.00d | 1.80d | LDPE | 0.70d | 2.00d | 2.00d | |

| ASA | 0.78d | 2.00d | 1.80d | HDPE | 0.75d | 1.80d | 1.80d | |

| PA4.6 | 0.73d | 1.85d | 1.70d | PET | 0.75d | 1.85d | 1.70d | |

| PA4.6 GF30 | 0.78d | 1.85d | 1.90d | PET GF30 | 0.80d | 1.80d | 1.70d | |

| PA6 | 0.75d | 1.85d | 1.70d | PMMA | 0.85d | 2.00d | 2.00d | |

| PA6 GF30 | 0.80d | 2.00d | 1.80d | POM | 0.75d | 1.90d | 2.80d | |

| PA6.6 | 0.75d | 1.85d | 1.70d | PP | 0.75d | 1.85d | 1.70d | |

| PA6.6 GF30 | 0.82d | 2.00d | 1.80d | PP TF20 | 0.82d | 2.00d | 1.80d | |

| PBT | 0.75d | 1.85d | 1.70d | PPO | 0.75d | 1.85d | 1.70d | |

| PBT GF30 | 0.80d | 1.80d | 1.70d | PS | 0.80d | 1.80d | 1.70d | |

| PC | 0.85d | 2.50d | 2.20d | PVC | 0.85d | 2.50d | 2.20d | |

| SAN | 0.77d | 2.00d | 1.90d | |||||

|

The high performance Plas-Tech® 30 Screw for Plastic is a direct screw fastener for use in thermoplastics. Its design characteristics include a profiled thread root to assist plastic flow and stress reduction, a 30 degree flank angle to reduce boss bursting forces and an 8 degree pitch angle which combine to support low installation torques with high stripping torque values. |

- Reduced radial stress

- No material jam in the core area

- Maximum resistance to relaxation

- No material stress through plasticisation